top of page

Latest

Search

Applications

Explore the many ways cobots are used across industries—from welding and painting to machine tending and inspection. This category highlights real-world use cases, showing how flexible automation can improve efficiency, reduce labor costs, and boost quality. Whether you're new to robotics or scaling up, find practical insights and inspiration to apply cobots in your own operations.

How Blue Sky Robotics Uses Human-Centered Design for Automation Solutions

Robotics is transforming industries of every scale. From manufacturing to logistics to custom fabrication, automated systems are no longer limited to massive factories with multimillion-dollar budgets. Today, small and midsize businesses are exploring robotics as a way to increase efficiency, reduce errors, and stay competitive. But the true breakthrough isn’t simply about adding more machines, it’s about designing automation that works with people, not around them.

5 min read

Are Robotics in Warehouse Automation Worth It for Small to Mid-Sized 3PLs?

Robotics warehouse automation refers to the use of intelligent systems, robotics, and autonomous machines to perform repetitive tasks in a warehouse—like picking, packing, transporting, and storing goods. These technologies aim to optimize operations by reducing human labor, increasing accuracy, and improving throughput.

4 min read

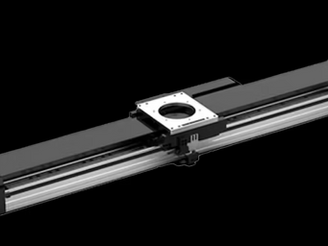

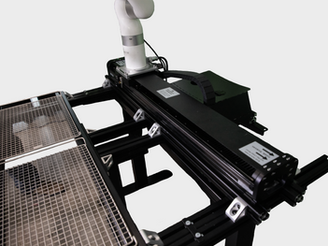

Direct Drive Linear Motor Applications in Precision Robotics: Key Uses and Benefits

Direct drive linear motor applications are redefining the standards of precision robotics by delivering high-speed, backlash-free motion with exceptional accuracy. This article explores how industries like semiconductor manufacturing, medical devices, and advanced automation benefit from these motors’ superior performance, reduced maintenance needs, and real-time responsiveness.

8 min read

Direct Drive Linear vs Traditional Motors: Which Is Better for Your Application?

When comparing Direct Drive Linear vs Traditional motors, the choice comes down to precision, speed, maintenance, and lifecycle costs. This guide breaks down how each motor type performs in real-world automation settings—helping engineers and decision-makers choose the right solution for their application.

6 min read

bottom of page