Automation Isn’t Just About Speed—It’s About Precision

- Caroline Peters

- May 19

- 2 min read

Updated: Aug 8

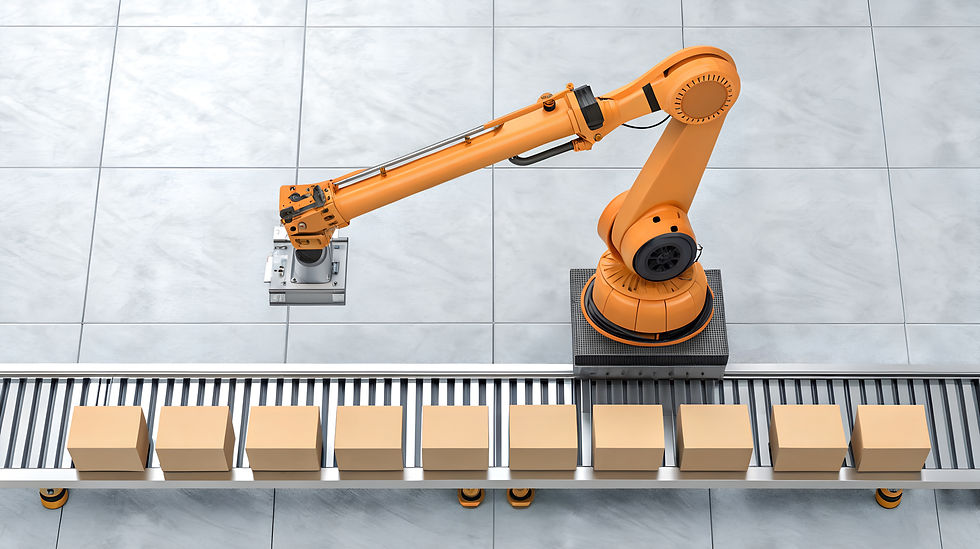

In modern manufacturing, consistency isn’t a luxury, it’s a necessity. When precision coatings or intricate fabrication are involved, even the smallest variations can lead to expensive rework or client dissatisfaction. That’s why automation is no longer just a labor-saving option. It’s a quality assurance strategy.

While many associate robotics with mass production, today’s tools are proving just as valuable for custom, short-run, or variable workflows, especially when output must remain flawless batch after batch.

When Consistency Matters More Than Speed

Robotic automation is redefining what’s possible in production environments that demand tight tolerances. While experienced human workers offer expertise, robots provide something humans can’t: 100% repeatability.

In one example, a robotic painting system was brought in to tackle matte black finishes, infamously unforgiving coatings that show every imperfection. The goal wasn’t speed, it was flawless sheen, thickness, and durability across thousands of parts.

The result? Mission accomplished. The robot maintained perfect consistency regardless of climate changes, workload, or batch size.

Beyond Labor Savings: Unexpected Wins

While quality was the driving factor, the introduction of automation brought unexpected benefits too:

50–70% less paint usage

Lower material costs on expensive coatings

Faster ROI—paid off within the first year

Increased operator productivity during cycle time

By laying down uniform coatings with minimal waste, the robotic system dramatically cut material usage, even though the spray duration was longer per cycle. Less overspray. Less error. More savings.

Flexibility Is the New Benchmark for Automation

Historically, most robotic systems were massive, rigid, and expensive, great for auto plants, not so much for smaller manufacturers. That’s changed.

Now, compact and modular robotic arms can be programmed for a wide range of tasks, making them ideal for high-mix, low-volume production. Custom fixtures, easy programming, and user-friendly interfaces make these solutions accessible without an in-house engineering team.

Look for automation systems that offer:

Easy reprogramming for new tasks

Quick setup and teardown for short runs

Integrated support to minimize downtime

People-First Automation Is the Future

Automation isn’t about replacing workers. It’s about amplifying their capabilities. In practice, operators don’t lose their jobs, they gain more control over the process, reduce strain, and spend more time on higher-value work.

When automation is done right:

Operators stay in charge of priming, prepping, or mixing

Robots handle repetitive precision tasks

Output improves, and morale often goes up with it

Adopt Early, Stay Competitive

The takeaway? Automation isn’t just for the biggest factories anymore. It’s scalable, customizable, and increasingly essential for maintaining quality in a competitive market.

Companies that wait risk falling behind, not just in efficiency, but in customer satisfaction and material costs. Those who invest early don’t just gain precision, they gain an edge.

Click here for more information on the AutoCoat System : https://www.blue-sky-robotics.com/autocoat-system