Why Cobot Capable Robots Are the Future of Flexible Automation

- Blue Sky Robotics

- May 19

- 2 min read

Updated: Aug 8

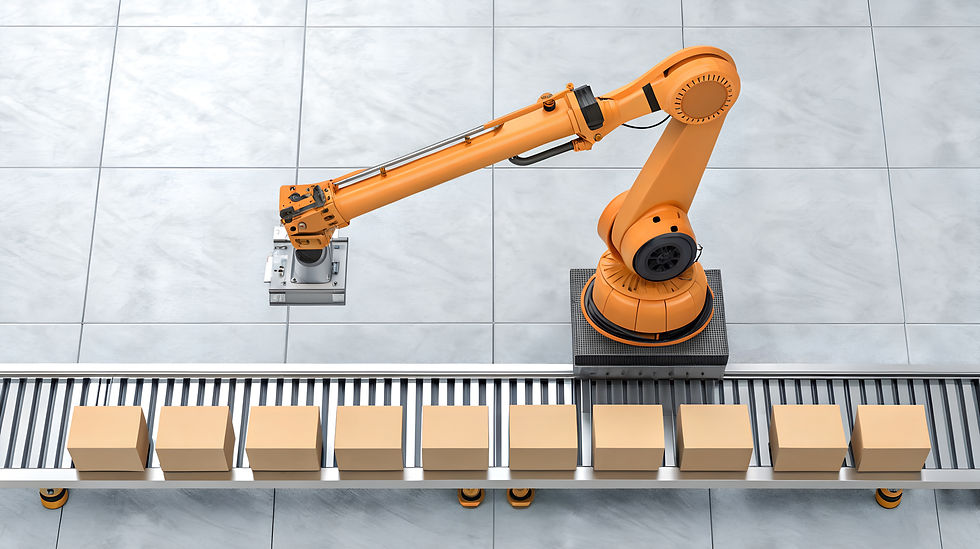

When you hear "robot," you might picture massive machines behind safety cages on a factory floor, but a new generation of robots is changing that image. These collaborative robots are designed to work side by side with people, safely and efficiently.

Unlike traditional industrial robots, cobot capable robots don’t need to be fenced off. They’re lightweight, flexible, and adaptable to many environments, whether it’s a small business, a warehouse, a lab, or even an office. Their ability to handle repetitive or delicate tasks makes them ideal for enhancing human productivity.

What Makes Cobot Capable Robots Different?

They work safely alongside humans

Perfect for high-volume, low-complexity tasks

Lower deployment costs due to reduced safety requirements

Cobot capable robots are also highly flexible. One can be reprogrammed in minutes to switch tasks, no need for custom coding or extensive setup. From assembling parts in the morning to sorting packages in the afternoon, they adjust based on your business needs.

Intelligence Meets Accessibility

Today’s cobot capable robots are powered by AI and computer vision, enabling them to:

Detect and identify objects with cameras and sensors

Adapt to positioning changes in real time

Be trained on new tasks without advanced programming

With intuitive interfaces and drag-and-drop programming, employees with no technical background can quickly learn how to operate them. This makes automation more accessible for teams across industries.

Why Cobot Capable Robots Make Business Sense

Cost Efficient: Minimal facility changes, reduced labor for repetitive tasks

Precise: Sub-millimeter accuracy makes them ideal for delicate tasks

Scalable: One robot, many roles—use it across departments and shifts

Cobot capable robots can perform tasks that demand 0.1 millimeter precision—like circuit board placement or consistent product packaging—without tiring or making errors.

Real-World Use Examples

Warehouses: handle sorting and packaging

Labs: process delicate samples with consistency

Manufacturing: handle repetitive motions that can cause human fatigue

With customizable end-effectors, from suction cups to claw grips, cobot capable robots are tailored for specific needs. Some can even grip delicate items like eggs without breaking them.

Cobot Capable Robots Are Here to Stay

They aren’t replacing people, they’re enhancing what people can do. Businesses that embrace this technology gain a competitive edge through improved safety, productivity, and flexibility.

The future of work isn’t about robots replacing humans. It’s about humans and robots working together, and that future has already begun.